While there are many methods of extraction, hydrocarbon extraction equipment is often selected for the creation of extracts including isolate/sauce, distillate, shatter, wax/sugar, tincture, and edibles. A Hydrocarbon Distillation Unit is a solvent cleaning system or hydrocarbon solvent cleaner used for butane cleaning prior to butane extraction with a hydrocarbon extractor.

Operators running hydrocarbon extractors typically distill butane solvent through their extraction system to clean the solvent prior to adding biomass. Only once this run is complete does an extraction run occur. Then, every time the solvent tank needs to be topped up, extraction ceases so that another run can be performed.

While necessary, these solvent distillation cycles waste time and reduce overall process efficiency. But, by adding an external Hydrocarbon Distillation Unit, butane solvent can be distilled prior to running it through solvent extraction equipment.

Why Add a Hydrocarbon Distillation Unit?

Cleanliness

By running solvent through a hydrocarbon extraction system to distill it, the extractor is being contaminated by the very act of distilling the solvent.

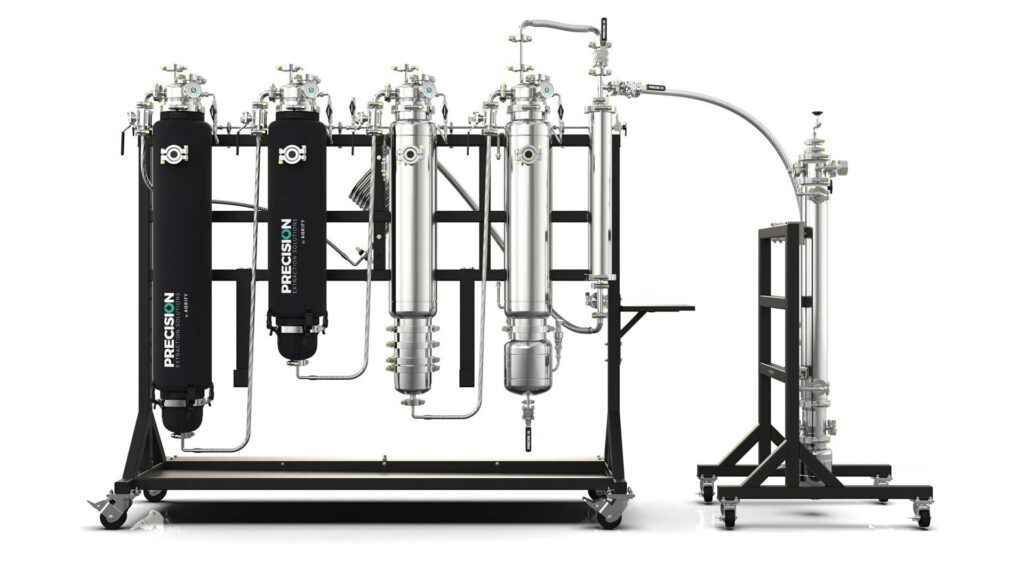

A Hydrocarbon Distillation Unit (HDU) is positioned between the source solvent tank and the extractor. The solvent (butane) goes from the source solvent tank, through the HDU, where it is distilled, and then into the extractor. By decontaminating the hydrocarbon solvents in a contained place (the HDU), uncleaned solvent never enters the extractor.

Efficiency

Any time solvent is being run through an extractor is time that’s not spent extracting. Moreover, anytime a solvent refill is required, the extraction process is halted so that the solvent can be cleaned before extraction commences.

With an external HDU, solvent is continually being distilled, minimizing the need for solvent-only cleaning cycles. This is time that can now be spent running additional extraction cycles. In tests with the HDU and Precision’s PX5 extractor, operators found they could add 1-5 extra cycles per day, equating to increased efficiency, productivity, and ROI.

What to Look for in Hydrocarbon Cleaners

Certifications and Compliance

Why is certification and compliance so important? Certification, compliance, and peer reviews ensure that equipment meets basic safety standards and performs as intended. Some certifications are country-specific, others voluntary.

Precision takes safety seriously and the HDU is the first engineer peer-reviewed hydrocarbon solvent cleaner on the market. This means it has been rigorously tested both by Precision and by outside engineers, to ensure unbiased testing before release.

Compatibility

Precision’s HDU works with both new and legacy hydrocarbon processing equipment including the PX1, X10, X40, PX5, PX10, and PX30, and several other hydrocarbon extractors in the industry. To ensure compatibility with your butane extraction equipment, contact Precision for a custom evaluation.

Adding an HDU to your hydrocarbon extractor will not only save time and increase daily process capacity but ensures cleaner extraction equipment. Are you ready to minimize contamination and maximize your efficiency? Learn more about the HDU.