If you want to create quality products, learning how to vacuum purge your BHO extracts is critical to remove residual solvent after extraction. We explain the science & equipment.

Butane honey oil is a thick, golden sap-like cannabis concentrate that contains an abundance of cannabinoids and terpenes. This potent extract has been known by many names like butane hash oil or BHO, because it’s made using butane to extract the resinous material found in the cannabis plant.

During processing, BHO is vacuum purged to remove excess solvents, which allows for a clean and flavorful product. As part of an optimized post-processing workflow, the vacuum purge removes the residual butane from BHO so it can be used safely either medicinally or recreationally.

Vacuum Purging 101

Crude oil, the raw oil that’s extracted from cannabis plant matter during BHO extraction, is put in a vacuum chamber that reduces atmospheric pressure. This process lowers the boiling point of butane so the oil can be purged of butane without damaging any of the therapeutic or psychoactive compounds in the marijuana plant material.

At sea level, the weight of the atmosphere creates 29.92” inHg of pressure, which affects the boiling point of liquids. When there’s an increased atmospheric pressure, it takes more energy for liquids to boil, so their temperature will rise accordingly.

When the atmospheric pressure is lower at higher elevations, the boiling point for liquids goes down, too. The vacuum chamber used for vacuum purging lowers the pressure so that the solvent can boil off at a much lower temperature.

We’d suggest that the vacuum purging process is one of the most essential steps in making a quality BHO extract. It removes solvents used to create crude oil, helping ensure that your products pass state-mandated residual solvent limits.

Vacuum Purging Equipment

To produce a high-quality product, it is essential to know the best methods for purging your solvent. Different equipment will require varying lengths of time and temperatures to purge solvents from products like shatter or wax.

The Vacuum Chamber

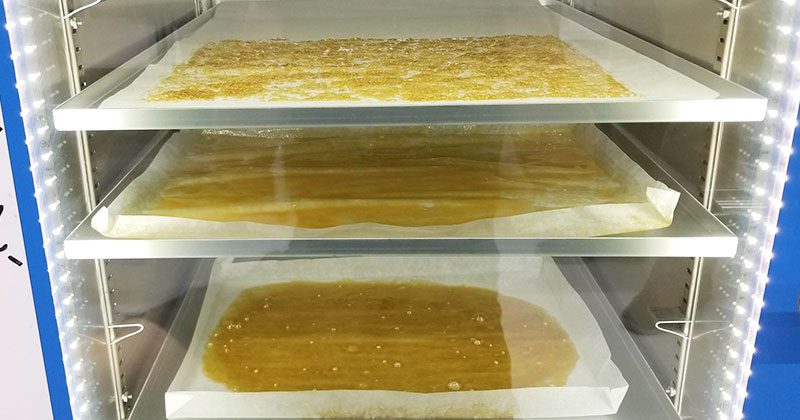

For vacuum purging, the best equipment will be able to heat every part of your extract evenly and quickly. A vacuum purge chamber has a stopcock valve that controls how much gas flows into the system at one time. Inside these specialty chambers, there are also racks or plates on which operators can place BHO. Commercially, the vacuum chamber includes shelving units where the technician can place several trays containing thin extract films. A vacuum chamber will also have a gauge to measure the atmospheric pressure in inches of mercury, designated in the form inHg or Hg.

The Vacuum Pump

Vacuum pumps are essential for a quality extraction process. The butane is evaporated by the vacuum pump to create a potent product with minimal impurities that cannot be achieved without it. To ensure that you have the best possible final product, make sure your equipment and accessories either contain no oil or possess a sealing capability, so that oil and other contaminants aren’t introduced into what would otherwise be pure extractions.

Types of Vacuum Pumps

There are several different types of vacuum pumps, some of which we’ve described below:

Diaphragm pumps are an excellent choice for cannabis extraction because they do not use oil and have many other benefits. These pumps can last a long time and save money in the long run but require a more significant investment upfront.

Rotary vane pumps use oil to lubricate the pump components. This is a disadvantage of these units because they are more likely to require maintenance and repair. These pumps operate at close-to-zero pressure for extended time periods, but require more regular upkeep.

Oil-free and hermetically sealed scroll pumps are another option. The motor and bearings for the pump are separate from the vapor stream. This completely prevents oil contamination, which is one reason they are approved for use in cleanroom environments.

Diffusion pumps remove gas molecules from exhaust using a high-speed vapor jet in the form of a high-performance pump.

You may have also seen single-stage and two-stage vacuum pumps referenced. For a deeper vacuum level, faster butane outgassing, cleaner processing, and a quieter room, a two-stage vacuum pump is preferred. The two stages are creation of the vacuum and cleaning of the system, which, when combined make for a more efficient process and a better choice.

Parts of the Vacuum Pump

Knowing a bit about the specific parts of the vacuum pump, and the part they play, is important to understanding how the system, as a whole, operates.

The Ball Valve

A ball valve can help keep any oil from the pump crankcase to spill into an extraction chamber. The ball valve allows you to close off a vacuum line when the pump is not in operation and provides safety with isolation valves, gauges, and filters for backfilling.

The Pressure Gauge

The compound pressure gauge is the single most important component of your vacuum pump system. To ensure you are running correctly, invest in a quality and calibrated instrument before beginning production. Never operate your vacuum ovens at positive pressure to avoid damaging valves or other components.

The Connecting Tube

The vacuum pump is one of the most important aspects of any suction system. The exterior pipe that connects to it should be durable enough for high-pressure purging, which means you need a tube designed specifically for your machine and not just one with an arbitrary generic design.

The Container

If you’re using a silicone mat for your thin layer of resin to place in your vacuum chamber, make sure it is a high-quality one. Low-quality mats have plasticizers that can absorb into the crude oil and create hazy white sections on the material. One way to tell if this has happened is when twisting or bending the silicone; if there’s any change from its original color then it very well may be contaminated with plasticizers. A parchment paper or pyrex dish can work as an alternative.

How-To Vacuum Purge 101

The last step in making high quality and flavorful BHO is vacuum purging. While each lab operation may have some unique aspects to their process, we’ve spelled out the basics below.

Step 1:

Place the BHO on an appropriately-sized silicone mat, parchment paper, pyrex dish or PTFE paper in the center of your device. Set it at your desired temperature and pump up to near a full vacuum before setting the final temperature to around 100 °F.

Step 2:

Monitor the bubbling of the BHO as you increase the vacuum. If it starts to bubble more, then butane is likely still present in your extract. Over time (hours or days), there will be fewer bubbles. This indicates that any remaining solvent has been removed from the product by outgassing. Outgassing may take longer if room temperature is lower. Once the bubbles stop and there are no changes in texture or consistency, it means that vacuum purging is complete.

Step 3:

Once you have achieved your desired purging cycle, flip the slab of BHO onto a clean silicone mat and repeat with more exacting parameters. You will notice that during this round there is not as much bubbling, but some bubbles should still be present.

Step 4:

To achieve different desired end products like wax or shatter, manipulate the temperature and pressure while flipping the slab of BHO and continuing to process it in the vacuum oven.

Equipment

Precision Extraction experts ares here to help you design a lab to launch your success. From the butane extraction equipment that fits your production goals to all of the ancillary equipment, including our Cascade Sciences vacuum ovens and pumps, we have the end to end solution to help you produce a broad range of the best-selling concentrates. Learn more about the Best Butane Extraction Equipment.