CBD Extraction is the process of isolating and extracting Cannabidiol from the base cannabis plant material, using some form of solvent, such as hydrocarbon or ethanol– these solvents attach to the desired compound, allowing the unnecessary plant material to be washed away.

With the passage of the 2018 Farm Bill, CBD is increasingly accessible to all Americans. It’s in teas. It’s in tinctures. It’s in chocolates, beauty products, balms… luxury products galore. These refined treats are the result of a refined and perfected CBD extraction process.

You might have quite a few friends already singing the praises of CBD for pain relief, sleep aid, or mood enhancement. And in the growing number of US states with marijuana access, CBD is a trendy component for edibles, tinctures, topical balms, vapor oils, and a host of other THC-oriented products.

As the cannabis industry booms and non-smoking cannabis products grow in popularity, so does CBD extraction technology. And the craft of cannabis extraction is hardly new.

Extraction: From Plant to Product

Extraction, at the most basic level, employs liquids – or solvents – to isolate the desired chemical compounds in a plant, remove them, and consolidate them for new use. Different extraction methods use different solvents, which require specific processes, temperatures, and pressures.

Some solvent processes require more care than others. Higher temperature treatments run the risk of destroying delicate cannabis terpenes. Lower temperature methods are easier to keep safe but generally have a higher cost of operation and upfront equipment costs.

Budget, scale, safety, and end product… all of these factors vary by CBD extraction method. But some principles hold true across the industry: safety, consistency, and quality are always essential, no matter what method you choose.

CBD Extraction Methods: Pros & Cons

Here is a run-down of the most popular extraction methods.

Ethanol Extraction

Ethanol extraction is maybe the oldest industrial method. The plant is washed with ethanol solvent at a low temperature with low pressure.

- Pros: Safe method. Relatively inexpensive. Efficient yield.

- Cons: Hard to adjust – or ‘tune’ – for sensitive compounds. Plus, the ethanol attaches to water-soluble molecules that are less desirable for an extract – specifically chlorophyll, which has a bitter taste and is undesirable. Subsequent processing can remove chlorophyll but often lowers the CBD volume as well.

Carbon Dioxide (CO2) Extraction

The food industry has used this method for years – for example, it removes caffeine from coffee beans. CO2 is applied in high pressure at low temperature, which renders the gas to a “supercritical” liquid that extracts CBD.

- Pros: No flammability risk. Adaptable, adjustable, easily tuned.

- Cons: Higher equipment costs (around $100,000). Slow extraction (8-10 hours). The complicated extraction process requires extensive training and is difficult to automate.

Hydrocarbon Extraction

Another process familiar to the food industry, hydrocarbon solvents include any organic compounds containing only hydrogen and carbon. Most commonly, it’s propane or butane washing over the plant at low temperature at low pressure.

- Pros: Consistent, high yield. Fast extraction. High potency. Full-spectrum results. No chlorophyll. Low cost equipment ($35,000).

- Cons: Currently, limited options for large scale automated manufacturing. But more and more industry leaders are embracing hydrocarbon methods.

Why Hydrocarbon Extraction is Leading CBD Extraction

What sets hydrocarbon extraction apart is simple: a fast, efficient process with dynamic results. Unlike ethanol, hydrocarbons do not extract water-soluble molecules. Meaning: no bitter, grassy chlorophyll in the final product. At a low temperature, hydrocarbon extracts more cannabinoids and terpenes and preserves their complex aromas and flavonoids. It maintains the ‘full-spectrum’ oil – keeping the vitamins, nutrients, and fatty acids known to be beneficial in many plants. And it preserves these delicate structures because no extreme purification follow-up is required.

Hydrocarbon method requires more attention to safety and process than some cruder methods, mainly since the solvents are flammable. But butane and propane are recognized as safe by the Food and Drug Administration. And, ideally, any extraction lab will prioritize safety precautions no matter what method they employ.

The extracts that come from the hydrocarbon process are exceptionally versatile, leading to a reputation as the ‘fresh-squeezed juice’ of the extract world. They’re used to create a wide array of delicious, complex, and safe oils, shatters, waxes, and more.

How the Hydrocarbon CBD Extraction Process Works

It all begins with the plant, the same way that a high-quality juice starts out with excellent fruit. If you start with a higher cannabinoid plant, you’ll result in a higher-cannabinoid product. Maintaining the quality of that plant from the time it is picked to the time its processed means storing it in a controlled environment – taking care to avoid sunlight, oxygen, and heat.

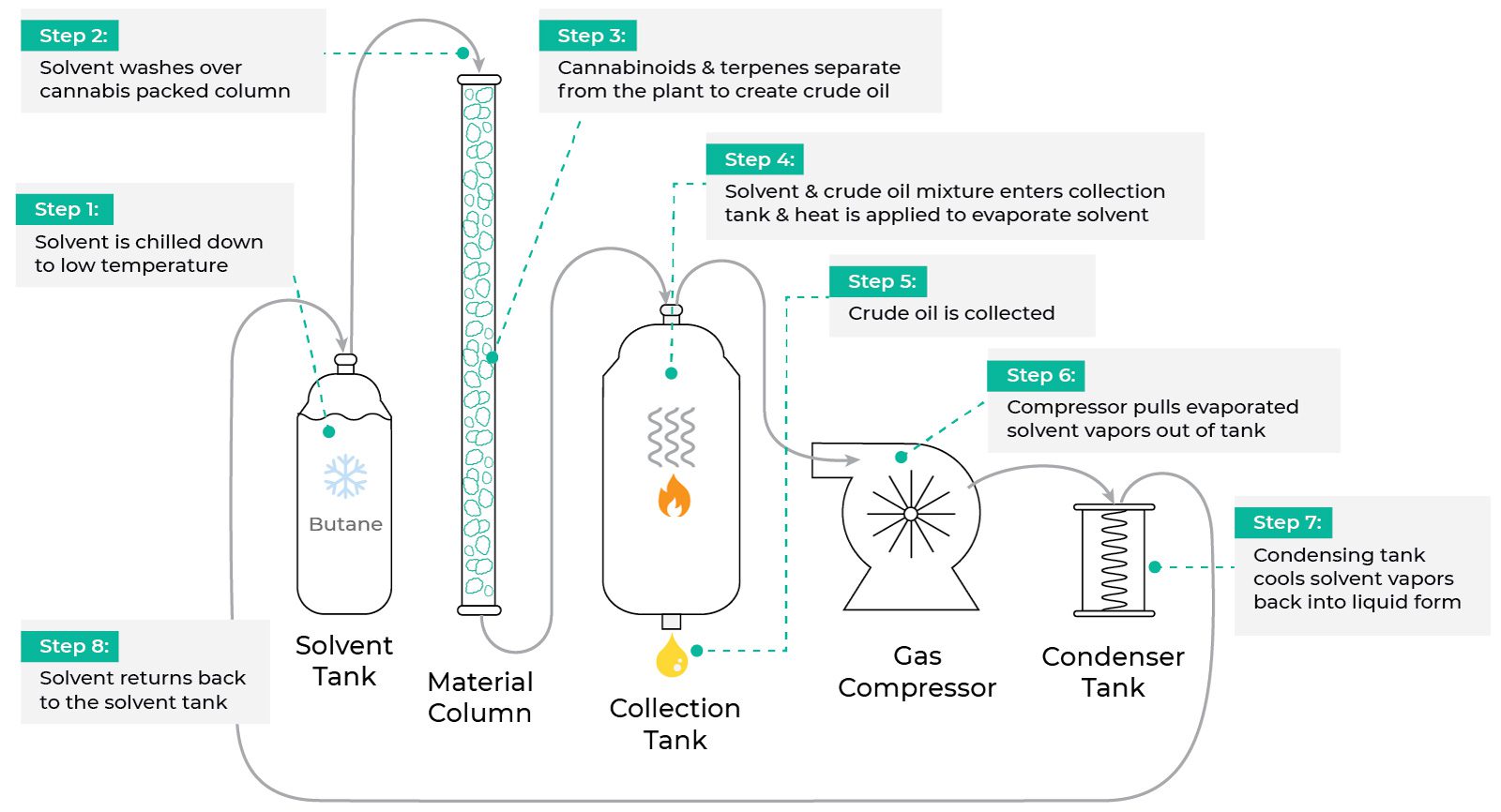

Washing

Cold solvent, usually liquid butane, washes over the plant. In doing so, the compounds dissolve – or in other words, transfers – cannabinoids and terpenes from the plant to the liquid. The solution is then separated from the plant. When chilling your solvent to super low temperatures, like -90°C, you can avoid having to do an inline dewax to remove fats and waxes.

Collection

The solution which contains solvent and your oil from the plant is then separated into a new tank where the solvent is evaporated with heat. The desired extract, or crude oil, is then collected at the bottom of the tank and can poured off.

Solvent Recovery

The separated solvent vapors which were evaporated in the collection tank are now pulled out by a compressor. Both the compressor and an attached condensing tank cool the solvent vapors and return the butane back to liquid form, where it returns to the original tank and will be used in subsequent extraction processes – this is the ‘closed loop‘ process.

Purification

The final purification steps vary depending on the type of product desired. This might include a centrifugal approach, a vacuum purge, or a co-solvent separation, among others. And your fresh, pure extract is complete!

CBD Extraction Equipment

People are eager for increasingly refined CBD products, and Precision technology can deliver it. With better extracts, your options for product design grow too. With more efficient production, your business becomes more and more dynamic.

Precision® CBD Extraction Equipment

- Hydrocarbon and Ethanol Solvent Extractors

- Systems for small to large scale processors

- Easy to use and easy to clean

- PSI certified and compliant in all 50 states

- C1D1 and C1D2 compliant equipment