Features

- Temperature resistant, Non-outgassing

- Less Mess. Very fine mesh keeps drying neat

- Allows for airflow thru entire product during decarboxylation or drying process

- Works in any kitchen convection / forced air laboratory oven

- Sewn with love in Oregon, USA. Supporting our local small businesses

Specifications

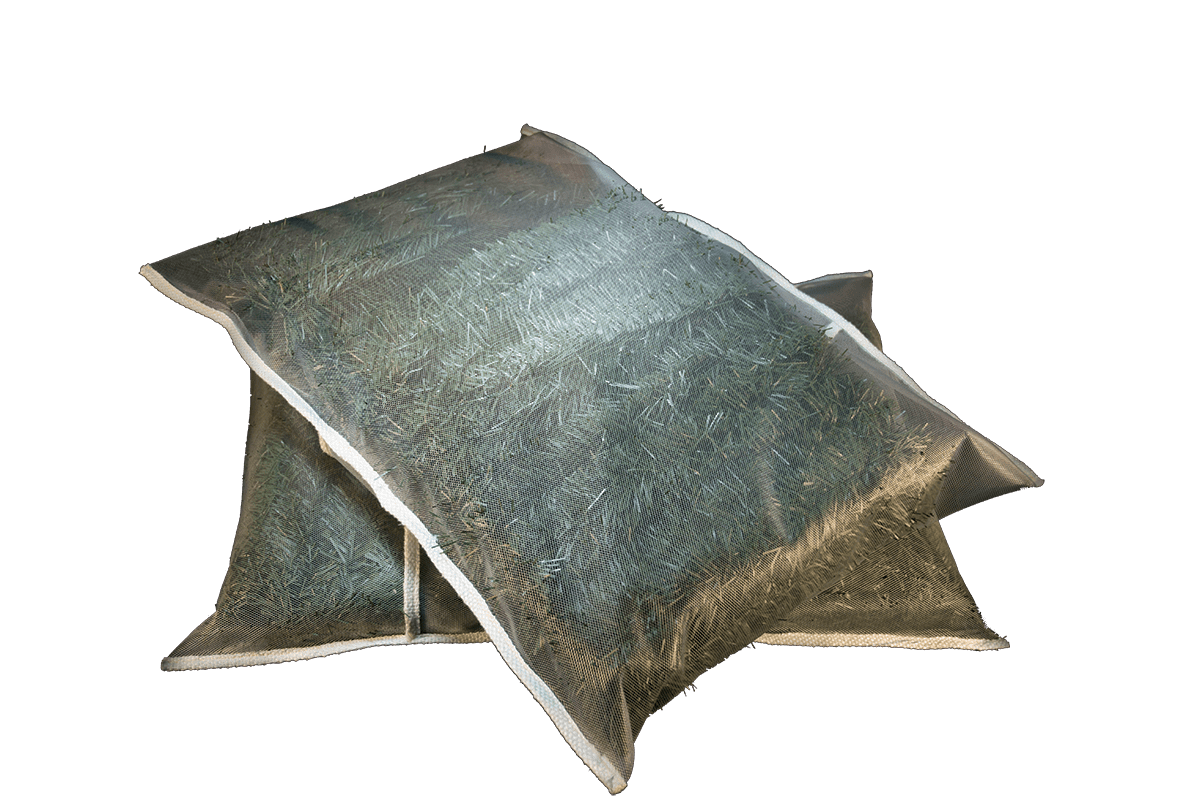

CDO-5 Mesh Bag

DIMENSIONS:

Width: 20.5″

Length: 15.5″

Thickness: 0.03″

OPEN AREA: 24%

HOLE SIZE: 0.018 x 0.018 in.

CAPACITY: Approx 2+lbs of medium ground material, 1 in. thick

RESIN (MATERIAL): Polypropylene (PP)

* Polypropylene products produced for some filtration applications are made from resin that complies with FDA regulations for food contact. The regulation compliance is product number dependent / specific.

* Impact at cold temperatures is likely to cause strand cracking or breakage.

RESIN GRADE: FDA Compliant

TEMPERATURE:

Melt Temperature: 363°F (161°C)

Softening Point: 300°F (150°C)

Heat Deflection Temperature: 194°F (90°C)

Glass Transition Temperature: 32°F (0°C)

CDO-28 Mesh Bag

DIMENSIONS:

Width: 28″

Length: 20.5″

Thickness: 0.03″

OPEN AREA: 24%

HOLE SIZE: 0.018 x 0.018 in.

CAPACITY: Approx 2+lbs of medium ground material, 1 in. thick

RESIN (MATERIAL): Polypropylene (PP)

* Polypropylene products produced for some filtration applications are made from resin that complies with FDA regulations for food contact. The regulation compliance is product number dependent / specific.

* Impact at cold temperatures is likely to cause strand cracking or breakage.

RESIN GRADE: FDA Compliant

TEMPERATURE:

Melt Temperature: 363°F (161°C)

Softening Point: 300°F (150°C)

Heat Deflection Temperature: 194°F (90°C)

Glass Transition Temperature: 32°F (0°C)

Compliance

The mesh bag material conforms to relevant parts of FDA 21 CFR 175-178 for direct food contact and has passed the USP Testing for Class IV Plastic.

General temperature performance from the manufacturer states a softening point of approximately 150°C / 300°F. Because the material is used in a wide variety of conditions/processes, the stated temperature parameter for softening may or may not apply to a customer’s specific use.

Ultimately customers must make their own determination that use of this mesh bag is safe and suitable for their intended application. These mesh bags are considered consumable items that do degrade and should be expected to be replaced with continued use.