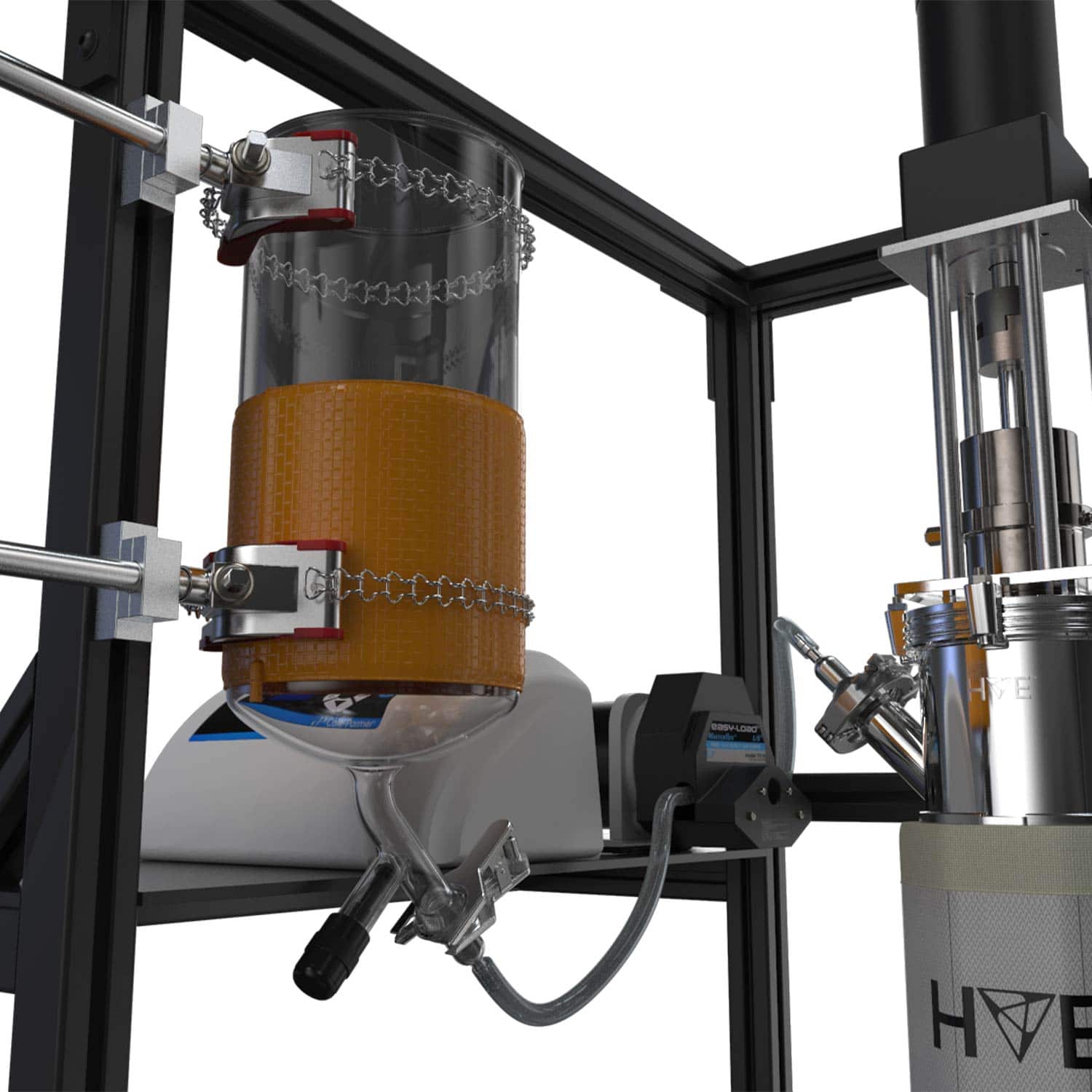

Pictured: HiVE™ Thin Film Distillation System

Modular Processing Options

Choose between volatile stripping at higher rates vs. cutting/polishing with higher quality fractions. Quick release fittings allow the internal condenser or stripping cone to be swapped within minutes.

Short Path Thin Film Operation

(Internal Condenser Installed)

- Best for medium to heavy compound stripping and polishing

- Maximizes condensation efficiency via short vapor path length

External Condenser Thin Film Operation

(Stripping Cone Installed)

- Best used for volatile stripping, higher vapor pressure compounds

- Allows lighter compounds to exit evaporator as vapor path is extended

Competitive Advantage

Customizable Processing Vapor Paths via Unique Configuration Options

The dual-port design allows for co-current and concurrent vapor path configurations, and a reversible wiper motor with vectored blades allows for tailored material residence times.

Fast & Easy Assembly and Cleaning

One tool, one person, 10 minute assembly or breakdown reduces cleaning and system downtimes, increasing your bottom line. Clean with your desired solution, while at high temps, without damage to the evaporator body and/or components.

Faster Cycle Times via High-Quality Materials

Stainless steel construction allows for quick heating and cooling, allowing for accelerated system startup and cooldown cycles. Proprietary Aerogel insulated thermal wrap ensures consistent temperatures while also increasing heat retention resulting in reduced power costs and increased performance.

High Expandability & Portability

Modular 80/20 frame allows for aftermarket upgrade options and mounting auxiliary gear.

Features

HiVE15 Features

- 0.15 m2 surface area

- 1-2 LPH final distillation feed rate;

- 2-4+ LPH volatile stripping feed rate

- 240V single phase 4800 watt heat bands

- 304L stainless steel evaporator body, optimized for efficient temperature dispersion

- High surface area stainless steel, dewar-style cold trap

- Quick swap internal condenser and stripping cone

- Small footprint (20” x 24”) customizable modular tabletop frame

- Teflon-bladed wiper design with six (6) vectored blades allows precise material flow and residence time

- Universal quick disconnect fittings allows for quick setup and breakdown

- Wiper basket is 3.75” wide by 18” long; longest 4” TFD/WFE on the market

HiVE30 Features

- 0.30 m2 surface area

- 2-6 LPH final distillation feed rate; 2-10+LPH volatile stripping feed rate

- 230V single phase 6400 watt heat bands, extreme thermal flux density

- 304L stainless steel evaporator body designed for maximum thermal transfer

- High surface area stainless steel, dewar-style cold trap

- Quick swap internal condenser and stripping cone with condenser stand

- Small footprint (36” x 24”) customizable modular frame with adjustable shelves for existing auxiliary peripherals

- Teflon-bladed wiper design with six (6) vectored blades allows precise material flow and residence time

- Universal quick disconnect fittings allows for quick setup and break down

- Wiper basket is 6” wide by 21” long; longest 6” TFD/WFE on the market

Specifications

| System Specs | HiVE15, Single Stage 0.15m2 | HiVE30, Single Stage 0.3m2 |

| Distillation Feed Rate | 1-2 LPH | 2-6 LPH |

| Wiper Basket Dimensions | 3.75″ W x 21″ L | 6″ W x 21″ L |

| Electrical | 4800 Watts @ 240V (20 amps max) – Evaporator Heater

200 Watts @ 120V (5 amps max) – Feed Tank Heater 120 Watts @ 120V (1 amps max) – Main Motor |

6400 Watts @ 240V (30 amps max) – Evaporator Heater

600 Watts @ 120V (5 amps max) – Feed Tank Heater 180 Watts @ 120V (1.5 amps max) – Main Motor |

| Vacuum Pump | Minimum 10 CFM flow rate with at least 30 mTorr ultimate vacuum rating (LS-RV-18, CRVpro30) | Minimum 20 CFM flow rate with at least 30 mTorr ultimate vacuum rating (LS-RV-36, CRVpro30) |

| Recirculating Chiller/Heater | Minimum 0°C – 75°C range for standard operation

Higher Max. Temp, between 100°C to 200°C can be used Minimum 1800 Watts Heating Minimum 300 Watts Cooling at 20°C 500 watts @ 20°C for Improved Performance |

Minimum 0°C – 75°C range for standard operation

Higher Max. Temp, between 100°C to 200°C can be used Minimum 500 Watts Cooling at 20°C 1000 watts @ 20°C for Improved Performance |

| Cold Trap | Manual Chilling: Dry Ice + Isopropanol/Acetone, or LN2 for Chilling

Immersion Mechanical Chilling: Polyscience IP-80 with 1.75” Rigid Coil |

Manual Chilling: Dry Ice + Isopropanol/Acetone, or LN2 for Chilling

Immersion Mechanical Chilling: Polyscience IP-80 with 1.75” Rigid Coil |

Compliance

Warranty Information

Training

Precision offers the following on-site product installation and training with experienced extraction technicians:

- Extract Product Engineering

- Distillation Prep

- Distillation Training

More information

Continuous Upgrades:

- Discharge Pump Kit (DPK)

adds two (2) discharge pumps to the system; coupled with the FPK makes unit continuous - Feed Pump Kit (FPK)

adds a feed pump to the system; coupled with the DPK makes unit continuous

Pressure & Speed Control:

- Booster Pump Kit (BPK)

increased vacuum flow rates during stripping or high-vacuum distillation operations - Dual Pump Manifold Kit (DPMK)

adds a pump cart and manifold to quickly switch between vacuum pumps - Pressure Control Kit (PCK)

adds a precision pressure controller to accurately control high vacuum to atmospheric pressures