The extraction process for cannabis concentrate is a complex and often misunderstood subject. If you’re in the cannabis industry, it’s essential to understand the differences between butane hash oil (BHO) and carbon dioxide (CO2) extraction. This article will help you decide which method is best for your business – BHO vs CO2.

BHO vs. CO2 Extraction: What’s the Difference?

For the last few years, we’ve seen an increase in extraction methods for cannabis. The two most common methods are butane hash oil (BHO) and carbon dioxide extraction (CO2).

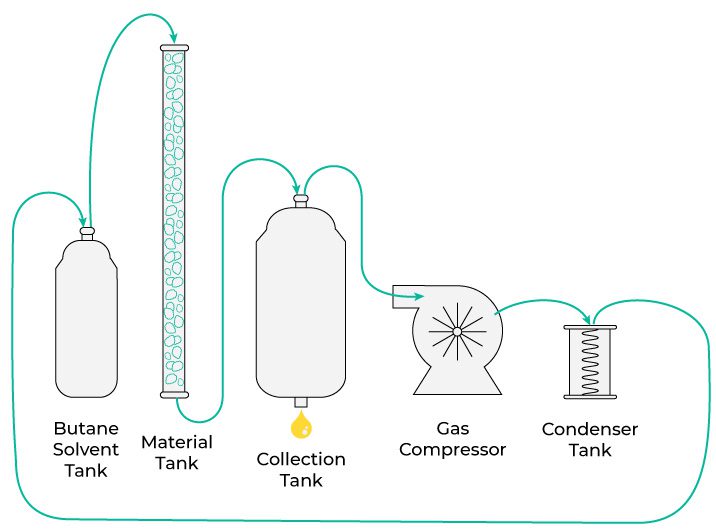

One of the most popular solvent-based concentrates is Butane Hash Oil (BHO). This extract is made by using butane, a light hydrocarbon solvent, to strip away resin from cannabis plants. This process requires closed-loop extraction equipment and specialized training; we don’t recommend this method for amateurs or at-home use.

CO2 extraction is a popular method for producing oil used in vape cartridges. It’s made with a high-pressure form of carbon dioxide as the solvent. This advanced extraction technique means you will, again, need professional equipment and training to ensure the safety of your team.

Cannabis Products From Extracts

There are all sorts of newer consumer-friendly products being manufactured using cannabis extracts. Wax, shatter, badder, and oil are a few popular forms that offer unique ways to consume cannabis. All of these were unknown even ten years ago when “hash” was the only type of concentrate available.

There are many misconceptions about the oil that’s processed to create cannabis concentrates. Both Butane Hash Oil (BHO) and CO2 Oil are made using solvents (butane or carbon dioxide in its “critical” or liquid state) to extract THC and other cannabinoids and terpenes from plant material.

Which Is Safer? BHO vs CO2

When run through a closed-loop system and in a safe, compliant environment, both BHO and CO2 extraction processes are perfectly safe. A closed-loop system offers a way of extracting concentrate from flower in an airtight environment.

CO2 extraction is popular because many believe it produces cleaner concentrates with no residual solvents, implying that the butane solvent used in BHO extraction leaves behind unsafe toxins and an unpleasant aftertaste overwhelming natural terpenes and flavors – which is untrue.

In fact, CO2 extracted oil will almost always have a secondary solvent, like ethanol, introduced in the post processing phase of making a product in order to winterize or crystallize, and that ethanol will need to be purged from the concentrate as well – much the same as butane extraction.

When appropriately managed by trained professionals, neither BHO nor CO2 extractions cause any more dangers than the other. While butane has been heavily criticized for open blasting systems, the process operates at a significantly lower PSI than CO2. A closed-loop BHO extraction system will often operate at never more than 150 PSI.

By comparison, a CO2 extraction system will often operate anywhere between 1,500 and 8,700 PSI. Because CO2 systems operate at these extremely high pressures, it is critically important to perform a number of preventative maintenance steps to ensure the consistent safety of the operator.

Which Provides the Superior Product? BHO vs. CO2

Many consider butane extraction to be scientifically superior to C02 methods for creating concentrates for a number of reasons. BHO extraction typically has less post processing requirements than a CO2 extracted oil and is the better way to produce high-quality, terpene-rich cannabis extracts.

In the process of making many craft concentrates with butane extraction (like wax, live resin or badder) you can perform your primary extraction, purge your solvent in a vacuum oven, and then take your product straight to the shelf!

In contrast, when using CO2 for extraction there is a heavy amount of post processing, because CO2 extraction will grab more moisture, lipids and waxes from the source biomass, and these undesirables will need to be filtered out of your oil. As a result, a CO2 extracted product is also going to have less natural flavor and a different consistency compared to a butane extracted concentrate. Flavor can often be reintroduced into a CO2 extracted product by adding separately extracted terpenes back into the mix, but it is unlikely to rival the best BHO concentrate on the shelf.

BHO Extraction & Your Lab

Precision is a leader in BHO and ethanol solvent extraction solutions, providing equipment and end to end solutions for extraction labs ranging from small to industrial scale. Our team of experts can provide:

- Safe and compliant lab design for BHO extraction

- Closed-loop Butane Extraction Equipment

- All necessary ancillary equipment for BHO (heaters, chillers, vacuum ovens, etc)

- On-site training for equipment, craft concentrate production, safety and more.

Learn more about our equipment or contact us today to speak with a rep.