CBD isolate is 99% pure CBD, often in the form of a white powder that can be mixed into drinks or taken sublingually. This option is often popular among people who are just beginning to explore the use of cannabis or hemp derived products or looking to avoid the euphoric high associated with THC. It is also a great option for people who want hyper-accurate doses of CBD and the flexibility to create their own customized mixtures in their preferred carrier oil or liquid.

Making CBD isolate requires more steps than creating a CBD oil, as you have to remove every other element, such as phospholipids and flavors, from the product. While the process is more complex and requires additional equipment, it creates a totally pure end product that is free of anything besides CBD.

Steps on How to Make CBD Isolate

Step 1: Extraction

To make any concentrate you first have to extract. Manufacturers can use either a hydrocarbon solvent, like butane or propane, or ethanol solvent. Typically, we see ethanol used for the production of CBD isolate often with the use of a larger commercial extraction system – like a centrifuge. Smaller extraction systems can be used, it just depends on your throughput goals.

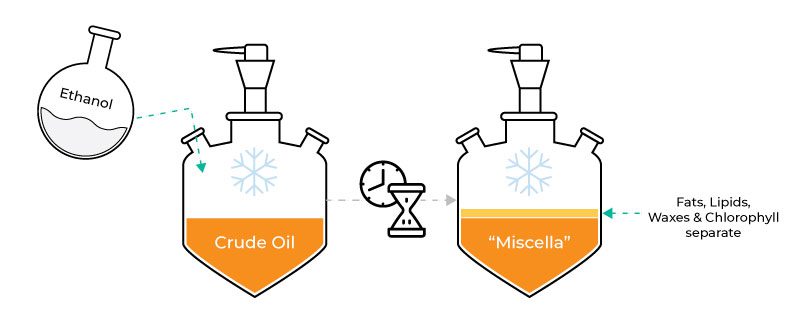

Step 2: Winterization

Winterization is the process of removing the fats, waxes and chlorophyll from the extract. Not removing these will lower the percentage and purity of the targeted CBD compound we are trying to capture. To achieve winterization you are essentially cooling down the extract to sub-zero temperatures with a solvent. Then, maintaining that chilled environment for a period of time in order for the lipids (fats and waxes) to coagulate and separate from the crude oil – now termed ‘miscella’.

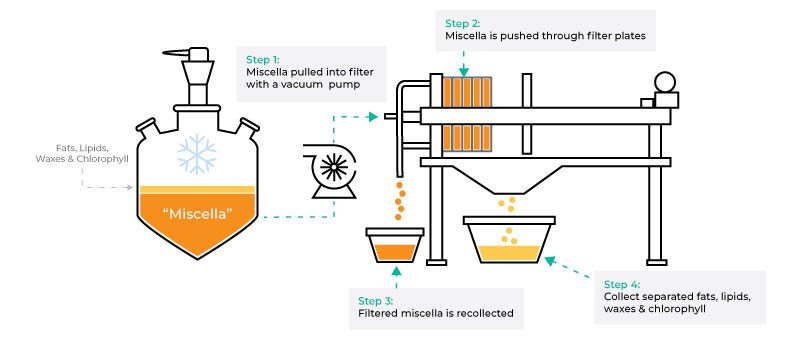

Step 3: Filtration

Once winterization has been completed it is necessary to now quickly filter those fats and waxes we coagulated from the miscella. A filter press is used with the assistance of a vacuum pump to pull the miscella mixture through a series of filter plates. Fats, waxes, etc are collected in one vessel and the desired miscella in another.

Step 4: Decarboxylation

In order to achieve optimal CBD content, decarboxylation is a critical step prior to distillation. The process of decarboxylation is to remove carboxylic acid and CO2 from cannabinoids present in the cannabis extract. Converting the acidic cannabinoid (CBDa) to its neutral form (CBD) ensures the end product contains all of the several benefits the cannabinoid has to offer. Furthermore, failure to remove CO2 from the extract will also affect the ability to properly form a vacuum in your distillation apparatus. The decarboxylation process is achieved through the application of heat in a reactionary vessel.

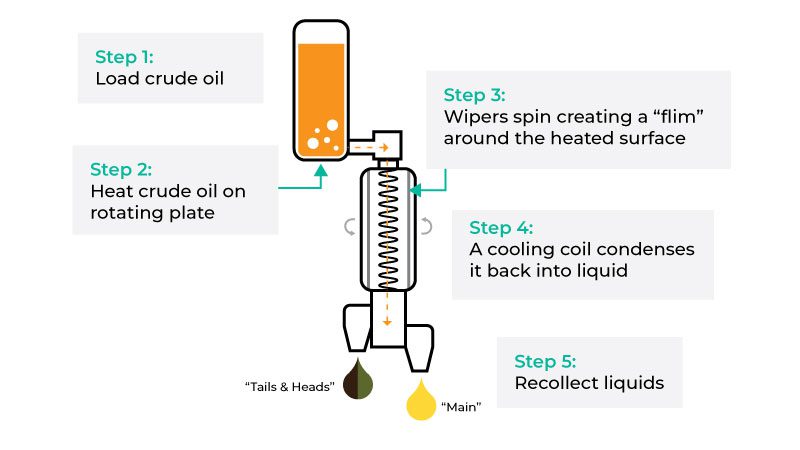

Step 5: Distillation

Now that our extract has been winterized, filtered and decarbed, we can perform distillation. There are short path and wiped film distillation apparatuses on the market, for the sake of this article we will use wiped film distillation.

While under vacuum, the extract is loaded into the feed tank where it passes over a heated rotating plate. From there, the heated oil then enters a secondary vessel where there are spinning wipers and a thin film is created around the heated, jacketed vessel. A long condensing coil in the middle of the vessel, cooled with recirculating fluid, recondenses the vapors back into liquid form. Receiving vessels then collect the CBD (known as ‘main body’) from the terpenes, volatiles and high boiling point cannabinoids (known as ‘heads’ and ‘tails’).

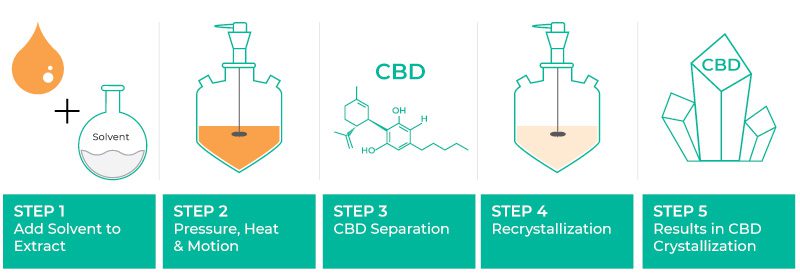

Step 6: Crystallization

An additional option that some manufacturers complete to change the structure of the CBD isolate is to subject it to a crystallization process. This process results in a final product that is still 99.9% CBD but has a crystalline structure.

This crystallization process is started by putting the CBD oil into a large vat, or reactionary vessel, with a stirring attachment. The mixture is heated while constantly being stirred. Then, the temperature is lowered and the rate of stirring is slowed down. Once the mixture has cooled and nucleation starts to occur (the initial stages of crystallization), the stirring rate is drastically increased, which causes the crystals to separate from the solution. After this, the crystals are rinsed with pentane, or another chemical solvent, to remove any remaining unwanted impurities.

Depending on what end product you’re trying to make you may prefer to use a CBD isolate powder when manufacturing lotions, edibles, beverages, etc. In order to make a powder you are simply taking the CBD isolate crystals and grinding them down into a powder-like substance.

Equipment for Making CBD Isolate

As system integrators for cannabis and hemp processing labs, Precision brings solutions to all stages of how to make CBD isolate. We believe our ethanol extraction equipment is just a catalyst for your vision, so we spent years refining our systems so you can make breakthrough products. Learn more about our C1D2 compliant ethanol extraction systems or talk to a Precision expert to build a tailored solution for your operation.