The BHO extraction process, which is effective in producing a good extract, can sometimes contain unwanted constituents that affect the final color and taste of the hemp or marijuana extract. The solution? Color remediation.

Through the color remediation process, the final extract achieved will be purer and have a more appealing color and taste, resulting in a higher-quality end product!

We’re breaking down the color remediation process in BHO extraction, from what it achieves to which equipment will best serve you.

What is Color Remediation?

Color remediation is the process of removing unwanted impurities from a hemp or marijuana extract by using a color remediation column (CRC). After color remediation has taken place, the final product will have a more appealing color, aroma, and flavor.

What Does Color Remediation Do?

Purifies

Passing your product through the color remediation column adds an extra step of purification to the final product. During the BHO extraction process, some impurities may be left behind after the initial extraction and refinement process. Color remediation is an additional purification step that ensures the final product is of the highest quality.

Achieves Better Color

As the name suggests, one of the main reasons people enact color remediation is to achieve a better color in the final product. If a lower-quality plant is used, the BHO extraction process can result in a final product that has an unappealing color and a strong taste from the presence of additional undesirables such as phospholipids, terpenes, and flavonoids.

Color remediation works to remove these undesirables that cause the unattractive color, so the final product has a translucent yellow color, similar to live resin. In general, a lighter color is associated with a higher-quality product, so color remediation is often used to transform the color of a lower-quality plant, which would typically have a darker, more brown appearance.

Some see color remediation as an opportunity to mask a lower-quality end product as one that’s higher quality, which has caused some controversy in the community.

Removes Unappealing Taste

Again, a lower-quality input will result in a final product that can have an unappealing taste to some individuals. Another benefit to CRC, the same undesirables that cause poor color in a final product are also in part responsible for the resulting poor flavor. By removing said undesirables a savvy operator can improve the flavor and purity of their finished product.

How to Achieve Color Remediation in BHO Extraction

Color Remediation Column

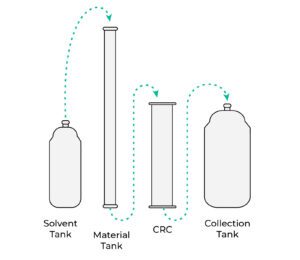

To achieve superior color remediation, a color remediation column, or CRC, is used.

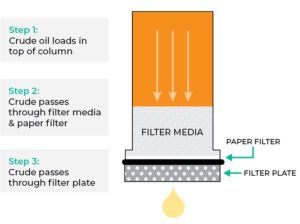

This ancillary piece of equipment utilizes a filter as well as filtering media such as clay, synthetic magnesium, and silica gel.

The combination of the filter with these substances allows the extract to be stripped of all impurities that are left behind from the BHO extraction.

Steps to Achieve

Achieving color remediation using a CRC is a relatively simple process, as the CRC is simply added on as an additional step in your extraction equipment setup.

The desired media is dried and subsequently packed into the column.

For simple color remediation the most common media combination is a mix of bentonite clay and silica gel.

These media, combined with the filter itself, will remove any unwanted leftover impurities.

The extract is forced through these media and the filter, and the purified final extract is collected at the end.

How Precision® Can Help With Color Remediation

CRC Skid – Chromatography & Remediation

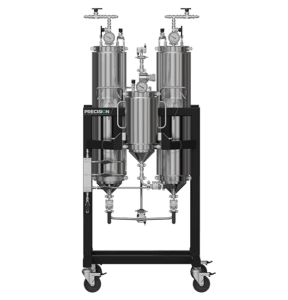

Precision’s CRC skid provides not only color remediation but also chromatography inline with your hydrocarbon and ethanol extraction system.

- Can be paired with virtually any primary extraction equipment

- Removes wide range of potential contaminants found in extracts

- Can be used for targeted isolation of cannabinoids, terpenes and flavonoids

- Temperature rated to -40C

- Equipped with two surge tanks

- C1D1 compliant

The PX Series of Hydrocarbon Extractors

The PX5, PX10, and PX30 all include inline CRC, providing flexibility in purifying extract through customizable filtration media remediating a wide variety of different contaminants in real time.